3D Printing on an Industrial Level

Joining your team, the Additive Manufacturing Innovation Centre researches, tests and brainstorms an effective solution to your manufacturing challenges. Leveraging cutting-edge Industry 4.0 technologies, we specialize in printing prototypes that propel your business forward.

Services

Product Development and Redesign

Whether you’re creating an entirely new product or improving an existing design, our experienced team can develop prototypes, production-ready components and other materials in additive manufacturing.

Our expertise includes reverse-engineering for cost-effective, high-quality part production. We can also help you explore new technologies in a cost-effective manner and match you with facilities suited to your needs.

Materials Development and Characterization

Have a specific product application in mind? Using novel materials can reduce production timelines and decrease costs compared to conventional manufacturing. We develop, test and validate these materials to create durable, lightweight parts for prototypes.

Our team also brings expertise in alloy development, paramater evaluation, and materials characterization to develop high-quality, functional custom components.

Process Optimization and Training

Today’s manufacturing challenges require practical, custom solutions designed to help your business maintain a competitive edge in an ever-evolving marketplace. Our team will work with you to evaluate the pros and cons of additive manufacturing for your products, or your entire organization.

Additionally, we offer tailored training and share data-backed information to enhance your team’s skills, improve workflows, and explore new facets of technology.

What Happens at AMIC

Beyond prototyping, AMIC provides production-ready and usable pieces. We understand the intricacies of each technology, offering consultation on process optimization, including time and materials, comprehensive assistance in forming a robust business case, and navigating the complexities of technology adoption.

Technology Evolution in Action

Since 2017, AMIC has achieved major advancements, continually raising the bar in quality and innovation, improving accessibility, and eliminating lengthy timelines and exorbitant costs.

Material Mastery

AMIC goes beyond testing materials; we redefine possibilities by experimenting with diverse materials, from cost-effective alternatives for initial testing to uncovering entirely new materials. Our expertise extends to crafting implants, satellite tech, and more, making them not just lighter but better.

Confidential Collaboration

Confidentiality is paramount at AMIC. Companies retain ownership of their intellectual property, and our team operates as an extension of the client’s team, exploring and testing solutions with a commitment to finding the best fit. See our Commercialization of Intellectual Property Policy Statement.

Consultative Excellence

Beyond prototyping, AMIC provides production-ready and usable pieces. We understand the intricacies of each technology, offering consultation on process optimization, including time and materials, comprehensive assistance in forming a robust business case, and navigating the complexities of technology adoption.

Leading Industry Solutions

AMIC leads the industry in prototyping, material exploration, enhancing efficiencies, and addressing specific business challenges. We evaluate technologies, scrutinise marketing claims, and provide a local, Canadian perspective on global opportunities.

Looking Forward, Acting Now

AMIC actively seeks and anticipates new technologies’ impact on Canadian businesses, fixing today’s problems, helping industries and incubators adopt technology seamlessly, and de-risking hurdles to steer businesses in the right direction. Join us in navigating the future of metal additive manufacturing by scheduling a meeting with AMIC—a journey of innovation and transformation awaits.

Ready to Embrace Change?

Book a meeting with the Additive Manufacturing Innovation Centre (AMIC) and talk to our experts about your organization or project.

Meet the Team

Colton Donald

Justin Valenti

Simon Coulson

Case Studies

See What Our Passionate Team of Problem Solvers Can Do

Experience the magic of IDEAWORKS: developing key insights for our partners and providing solutions that address challenges head-on.

Our Partners

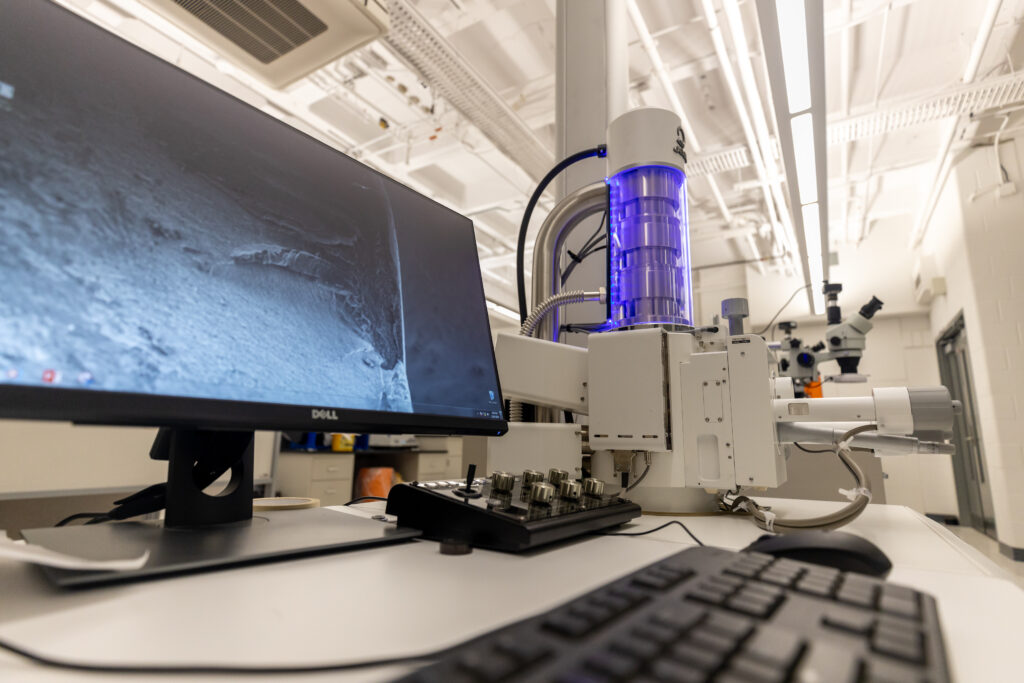

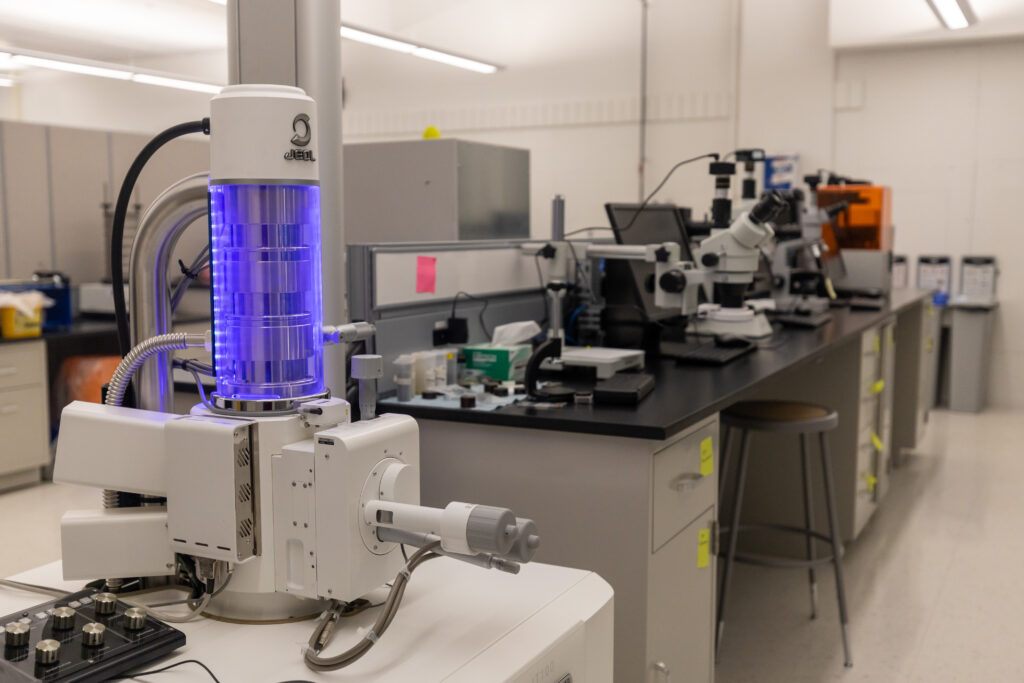

The AMIC Lab

Beyond the Prototype: Opportunities for Additive Manufacturing in Low-Volume Production

Uncover the game-changing use cases that will reshape your approach to production.

Additive Manufacturing Innovation Centre (AMIC) Whitepaper Download Form

Lets build the future together

Book a meeting with the Additive Manufacturing Innovation Centre (AMIC) and talk to our experts about your organization or project.